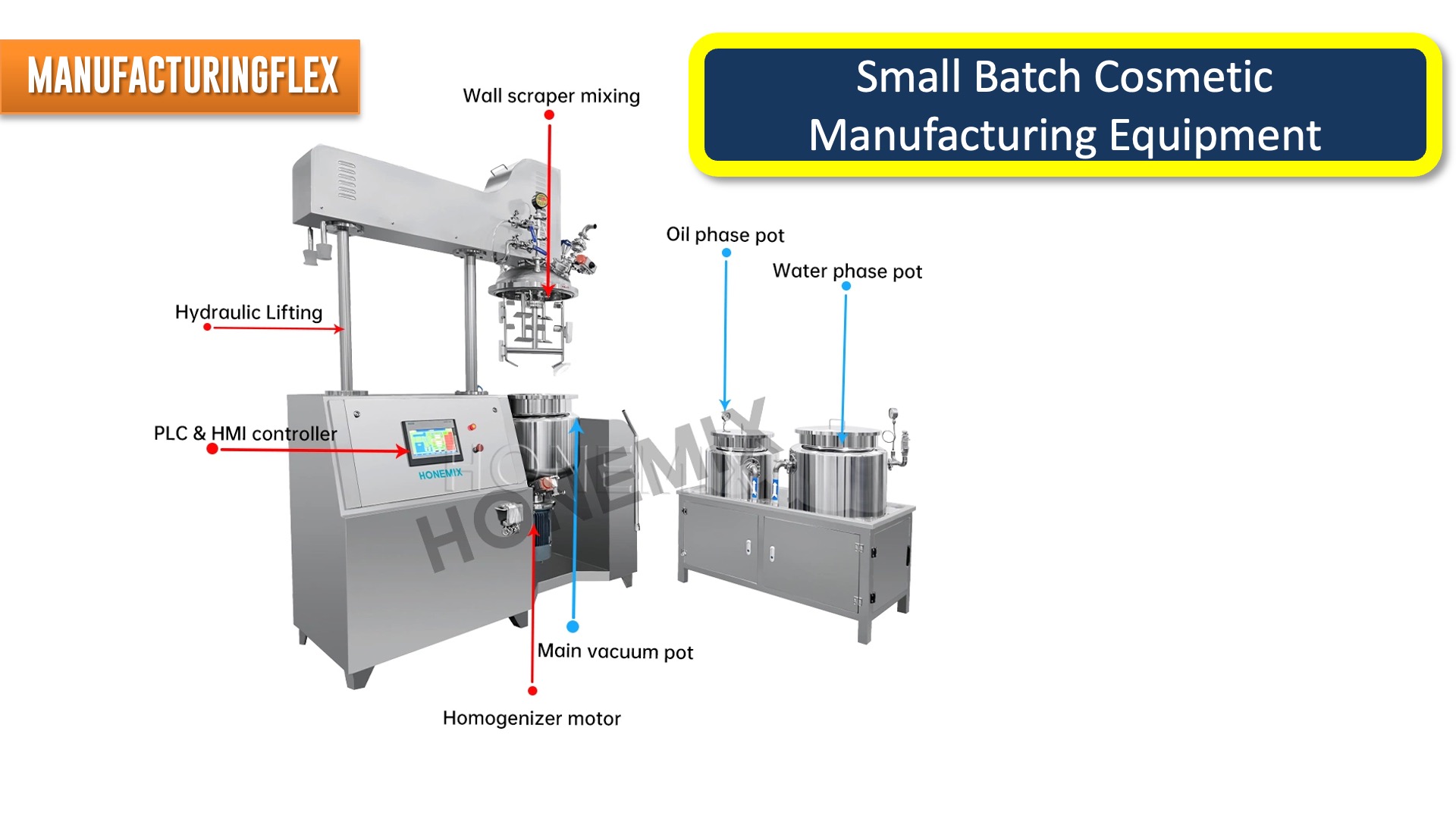

Mixers and blenders, emulsifiers, heating and cooling systems, fillers, labelers, sealers, pH meters, viscometers, packaging equipment. Small batch cosmetic manufacturing equipment is designed to cater to the production needs of startups, niche brands, or companies looking to produce limited quantities of cosmetic products. This specialized equipment allows for the efficient and cost-effective production of a wide range of cosmetics, from skincare products to makeup. The focus on small batches ensures flexibility, quality control, and the ability to respond quickly to market trends.

The equipment you choose can make all the difference in delivering high-quality products. Mixers and blenders are essential for achieving smooth and homogeneous formulations, ensuring that your ingredients are fully incorporated. Emulsifiers play a crucial role in creating stable emulsions, allowing water-based and oil-based ingredients to mix seamlessly. Heating and cooling systems are also important for controlling temperatures during production processes, such as melting or solidifying ingredients.

Fillers are another must-have piece of equipment for small batch manufacturing. They allow you to accurately measure and dispense precise quantities of your product into jars or containers without any wastage. Labelers and sealers ensure that your finished products look professional and appealing to consumers. pH meters help you monitor the acidity or alkalinity levels of your formulations, which is crucial for maintaining efficacy and stability.

Viscometers are handy tools for measuring viscosity – the thickness or flowability – of your cosmetic products. This information is vital for ensuring consistency across batches and meeting customer expectations. Lastly, packaging equipment allows you to efficiently fill jars, tubes, bottles, or other containers with your final product before they hit store shelves.

Investing in these essential small batch cosmetic manufacturing equipment not only improves productivity but also guarantees superior quality control over each step of the production process.

Types of Small Batch Cosmetic Manufacturing Equipment

Contents

The equipment used in small batch cosmetic manufacturing varies depending on the type of cosmetic product being produced. Common types include:

- Mixers and Blenders: For combining raw materials into a homogenous mixture.

- Emulsifiers: For creating stable emulsions, essential in lotions and creams.

- Fillers: For accurately dispensing products into containers.

- Labelers: For applying labels to product packaging.

- Sealers: For sealing the product containers to ensure product integrity.

Key Specifications and Performance Data

| Equipment Type | Capacity | Usage |

|---|---|---|

| Mixers and Blenders | 5 to 500 liters | Mixing raw materials |

| Emulsifiers | 1 to 100 liters | Creating emulsions |

| Fillers | Up to 50 units/min | Filling containers |

| Labelers | Up to 20 units/min | Labeling packaging |

| Sealers | Up to 30 units/min | Sealing containers |

Benefits of Small Batch Production

- Flexibility: Quickly adapt to market trends or consumer demand changes.

- Quality Control: Easier to maintain high quality in smaller production runs.

- Cost-Effective: Reduces the risk of overproduction and minimizes wastage.

- Customization: Allows for the production of personalized or custom-formulated products.

Applications in the Cosmetic Industry

Small batch cosmetic manufacturing equipment is used to produce a variety of cosmetic products, including:

- Skincare products such as creams, lotions, and serums.

- Color cosmetics like lipsticks, foundations, and eyeshadows.

- Personal care items, including shampoos, conditioners, and body washes.

Choosing the Right Equipment for Small Batch Production

Selecting the appropriate equipment involves considering several factors:

- Product Type: The nature of the cosmetic product influences the type of equipment needed.

- Production Capacity: Equipment capacity should match the intended production volume.

- Budget: Balancing the cost of equipment with the budget without compromising on quality.

- Space: The available space in the manufacturing facility can limit the size of the equipment.

Frequently Asked Questions (FAQ)

- What is considered a small batch in cosmetic manufacturing? Small batch production typically refers to producing less than 1,000 units per production cycle.

- Can small batch production meet regulatory standards? Yes, provided the equipment and production processes comply with industry regulations and standards.

- How does small batch production impact product shelf life? Smaller batches can lead to fresher products, potentially enhancing shelf life by reducing storage time.

Conclusion

Small batch cosmetic manufacturing equipment is a game-changer for startups and established brands alike, offering the versatility and efficiency needed to thrive in the competitive cosmetics market. By selecting the right equipment and embracing the advantages of small batch production, businesses can ensure product quality, meet consumer demand, and stay agile in a rapidly evolving industry.